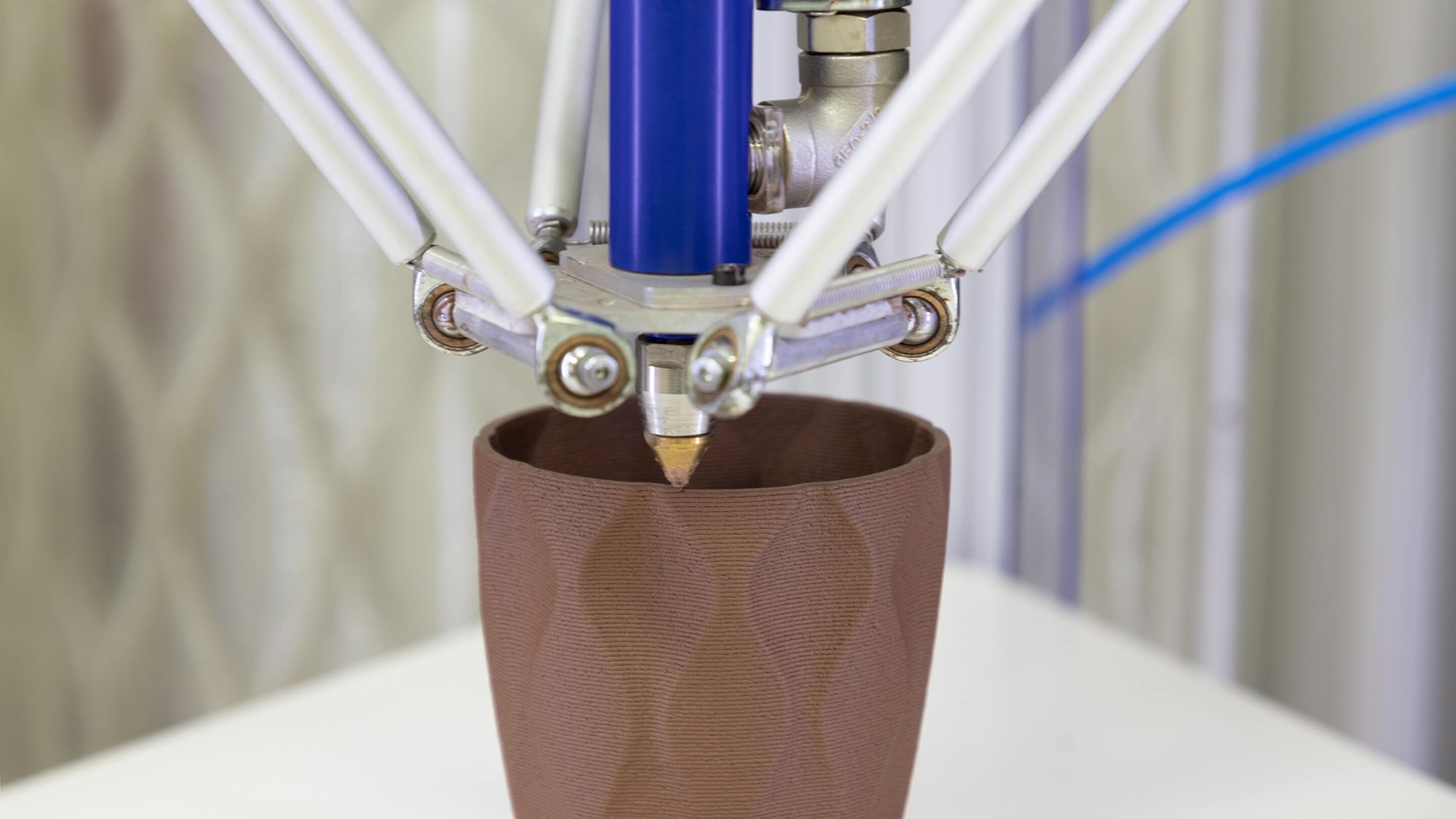

Delta WASP 40100 Clay

The Ceramic 3D Printer offers impressive speed and precision, capable of working with a wide range of ceramic materials. Its open design provides easy access from all three sides, allowing for seamless operator interaction throughout the printing process.

This printer can accommodate objects taller than 40 cm, with a maximum height of 1 m, enabling you to print directly from the floor. For select items, an additional steel printing plate can be mounted 60 cm off the ground, with a printing volume of 400 mm x 450 mm in height.

One of the standout features of this printer is its ability to continue printing seamlessly even if it is relocated, ensuring no interruptions in your workflow. You won't have to wait for the first object to dry before starting a new print.

Specifications

- Printing volume: Ø 400mm x h 1000 mm; (h 450 mm with interim plate)

- Minimum layer height: 0,5 mm;

- Maximum printing speed: 150 mm/s;

- Maximum travel speed: 150 mm/s;

- Acceleration: 500 mm/s2

MATERIALS

- Porcelain

- Earthenware

- Gres

- Refractory materials

- Clays and More

SUITABLE TOOLS

- LDM WASP Extruder: 1.5, 2, 3 mm nozzle diameter (standard)

- LDM WASP Extruder XL: 4 mm, 6 mm, 8 mm nozzle diameter

SOFTWARE

- Operative systems: WIndows, Mac, Linux;

- Official Slicing: Simplify3D®

- Compatible Slicing: Cura, Slic3r

- File type: .stl, .obj, .gcode;

INTERFACE

SD Card – Schermo LCD;

PHYSICAL DIMENSIONS

- Dimensions: 77 cm x 85 cm x h 195 cm (h 270 cm with tank support)

- Machine weight: 80 kg

- Dimensions for shipping the machine with wooden packaging: 100 cm x 100 cm x 230 cm, weight 130 kg

SUPPLY

- Input: 220/240 V 50/60 Hz (110 V available);

- Absorbed power: 200 W

- N.B.: Air compressor needed (min. pressure 8 bar)

TEMPERATURE

- Use: 20-30 C°;

- Warehouse: 0-30 C°;

MECHANICS

- Frames and carters: metal sheet (lowers the machine vibrations, grants the best print quality), aluminum, painted steel

- Print bed: bed in wooden multi-layer

- Movements: guides on anodized aluminum

Open sides give the possibility to stop the printer and interact with the part during the print

TECHNICAL INNOVATION

- No stop print: You can move the printer and not remove the object – each time the printing process has finished (this avoids to wait till the object has dried)

- Printing or from ground or from 2 printing beds at different Height.

- Extruder with controlled dosage thanks to a screw (2013).

- Controlled air pressure on the printer.

- Perfect stability thanks to new sliding-system on bearings.

- Dedicated Firmware

EXTRA

RESURRECTION SYSTEMA system which allow users to save their print job and resume it in the case of power failure.Read more about Resurrection System

FREE Z-SYSTEM

The machine measures the height of interruption of the print and it restarts there. Read more about Free Z-System