Biomaterials

Sustainable practices in our fabrication

We believe in biomaterials

We place a strong emphasis on researching and utilising renewable and/or recycled materials with our machines to produce parts, in order to minimise waste and carbon emissions.

PLA bioplastics are made from fermented plant starch such as corn, cassava, sugarcane or sugar beet pulp, all renewable and compostable resources.

PLA bioplastic can have up to 80% lower carbon emissions than fossil-based plastics like ABS. Thanks to its plant-based origin and cleaner lifecycle.

The renewable resources used in PLA Bioplastics are natural carbon sinks.

Based on VOC studies, PLA emits up to 30x fewer toxic compounds than fossil-based plastics like ABS when 3D printed.

PLA is mechanically stronger than common 3D-printing plastics like ABS and PETG under standard conditions.

PLA Bioplastic does not contain the hormone disruptors often found in traditional plastics - bisphenol A (BPA).

Recycling alone cannot be a long term solution for any plastics: All plastics have a limited life cycle, whereas PLA can be industrially composted.

We continually seek knowledge and insights by commissioning studies from both governmental and private agencies to critically examine the science behind bioplastics, ensuring our understanding remains informed and accurate.

Future’s materials are natural

Which eco-materials do we use?

Committed to minimising waste and carbon emissions, we use renewable and industrially compostable materials like PLA bioplastics, derived from corn, cassava, sugarcane, or sugar beet pulp. We also offer custom blends tailored to your creativity, incorporating unique elements like coffee, oyster shells and other materials. Contact us to explore creative and eco-friendly material options.

INGREDIENTS:

Fermented plant sugar based biopolymers (corn, cassava, sugarcane or sugar beet).

Clear PLA

In our workshop we primarily use PLA, a thermal bio-plastic derived usually from fermented sugarcane, known for its recyclability and compostability.

INGREDIENTS:

Recycled wood and fermented plant sugar based biopolymers (corn, cassava, sugarcane or sugar beet).

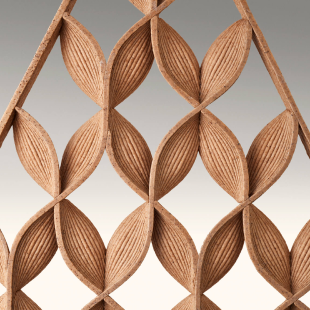

Wood PLA

In this variation, wood dust is blended with PLA to achieve a natural, raw timber finish that is soft to the touch.

INGREDIENTS:

Paper PLA is a blend of Polylactic Acid (PLA) from renewable sources and natural paper or cellulose fibers.

Paper PLA

This material combines the bio properties of PLA with the tactile feel of paper, creating a light weight material.

INGREDIENTS:

Recycled White PLA is made from repurposed PLA waste and contains white pigments for colour.

Recycled White PLA

Crafted from reclaimed White PLA, this variant upholds the characteristics of White PLA while contributing to circular partices.

INGREDIENTS:

Naturally occurring form of redearthenware clay and iron oxide.

Terracotta

Elegant and beautiful, this material allows for innovative designs within the material's inherent limits.

INGREDIENTS:

Flint, feldspars, flux composites, sand and clay bodies.

Stoneware

This clay variant features low porosity, showcasing a unique stone-like finish that combines durability with food safety.

INGREDIENTS:

Recycled fermented plant sugar based biopolymers (corn, cassava, sugarcane or sugar beet) and white pigments.

Plywood

We use laser safe plywood which has a low content of formaldehyde.

INGREDIENTS:

Natural Fiber

Natural Fabric

From cotton to jeans, untreated leather can all be laser cut to fit your specific needs

INGREDIENTS:

Wood Pulp

Cardboard & paper

Traditionally use in model making, any variety of cardboard and paper can be laser cut.

Curious About Our Biomaterials?

Explore our in-house developed eco-friendly materials.

Our custom PLA blends are designed with performance, fire safety, and regulatory compliance in mind.