Material Innovation at Fab.Pub

Where Design Meets Material Science

Explore our in-house brewed bioplastics, engineered for sustainability, performance, and storytelling.

Why Materials Matter

At Fab.Pub, we transform waste into design innovation. From wood dust and textile off-cuts to coffee waste, we turn discarded materials into beautiful, functional bioplastics. Our locally sourced blends, including basalt, and bamboo, reduce impact and celebrate sustainable, circular design.

Our In-House Material Brewing

We’ve developed custom materials to meet both aesthetic and technical demands in architecture and design:

Base Material: Clear PLA

Used in: Mandala Lamp, Custom Parts

Fab.Pure

Our signature clear PLA, renewable, stable, and versatile for prototypes and finished products.

Base Material: PLA Wood

Used in: Mandala Wood Stool, Interior Elements

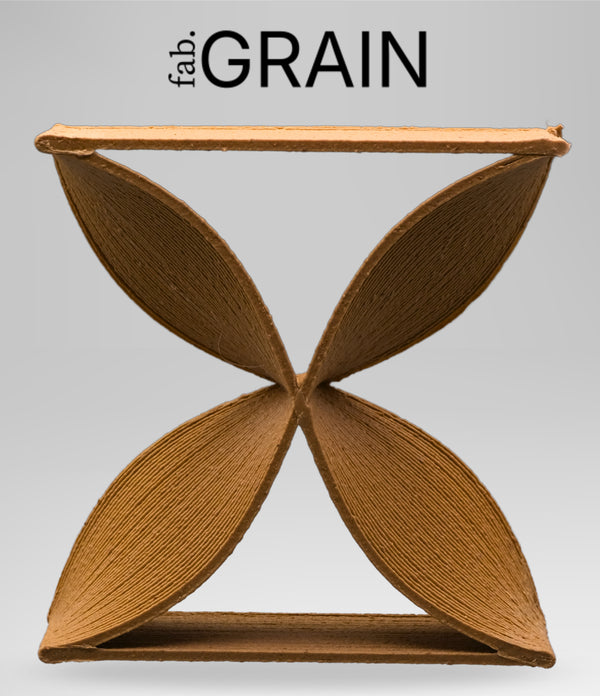

Fab.Grain

30% wood fibres and 70% bioplastics, offering a natural texture and warm finish.

Base Material: Flame-retardant PLA

Used in: Hyatt Chandelier, Pancras Square

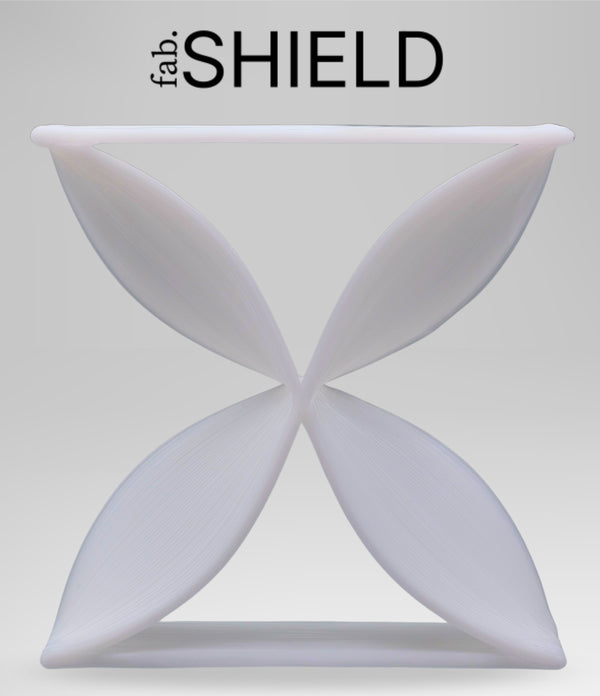

Fab.Shield

Flame-retardant blend designed for architectural use, certified for safety and performance.

Base Material: PLA Chalk

Used in: Under Development

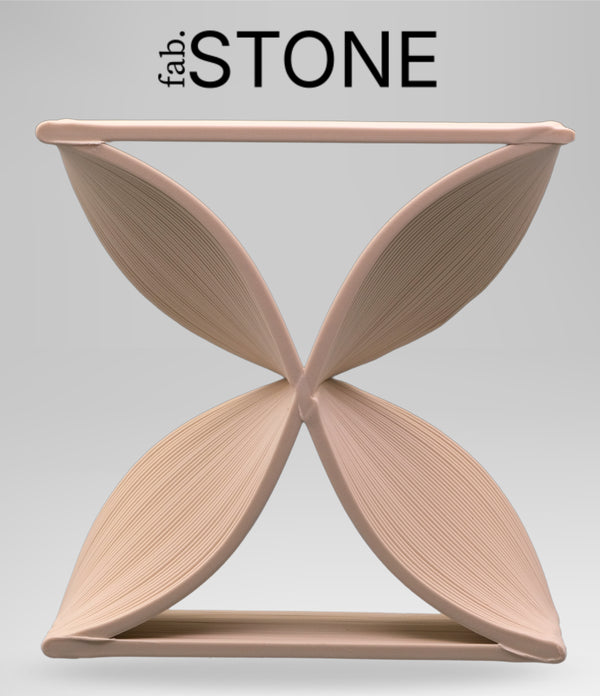

Fab.Stone

Chalk-infused PLA with a smooth matte finish and soft white tone.

Base Material: PLA Bamboo

Used in: Under Development

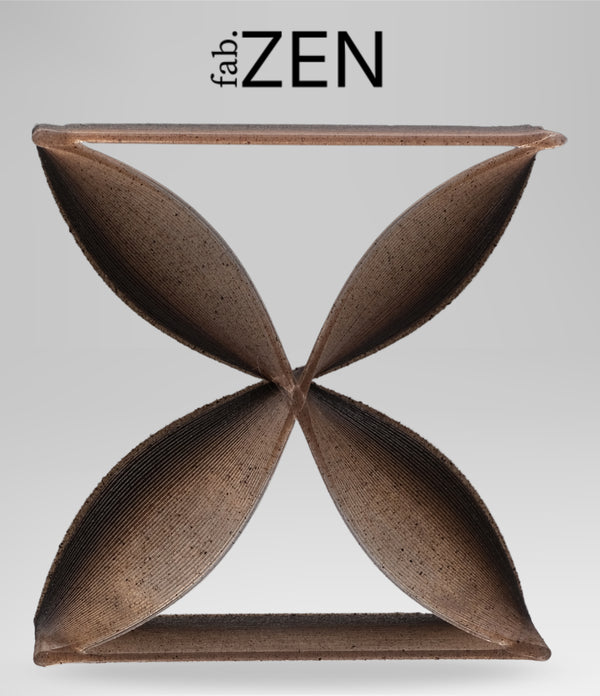

Fab.Zen

Light, organic material inspired by nature, ideal for decorative and interior use.

Base Material: PLA Basalt

Used in: Under Development

Fab.Lava

Durable, mineral-reinforced blend developed for strength and texture.

Base Material: PLA Coffee

Used in: Concept Products

Fab.Roast

Infused with reclaimed coffee waste for deep colour and subtle grain.

Why Bioplastics?

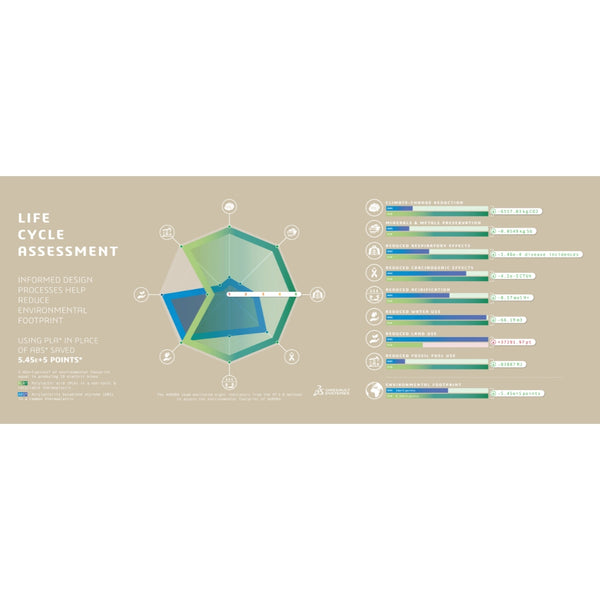

Our bioplastics are derived from renewable feedstocks such as corn and sugarcane, offering a low-carbon alternative to fossil-based plastics. Backed by the Life Cycle Assessment (LCA) conducted by Dassault Systèmes, the findings were further demonstrated through the Aurora Project, a collaborative installation developed at FabPub for the Design Museum’s Waste Age: What Can Design Do? exhibition.

The study compared Aurora’s structure in bio-sourced PLA versus petroleum-based ABS, revealing a carbon saving of over 6 tonnes the equivalent of building 10 electric bikes. The LCA confirmed that using PLA reduces emissions by over 5.4 kg CO₂ eq. per kg of material, while also lowering water and mineral use.

These results validate our approach to material innovation. PLA is industrially compostable, recyclable, and locally manufacturable, allowing Fab.Pub to design within a truly circular and science-led framework for sustainable architecture.

Design Backed by Science

LCA results show how PLA dramatically lowers carbon, water, and resource impact compared to ABS.

Aurora

Design Museum’s Waste Age: What Can Design Do?

PLA vs ABS: Environmental Impact

PLA shows lower impact across all key sustainability metrics.

The Science Behind Our Materials

Curious About Our Biomaterials?

For designers and fabricators, we also offer Compounding as a Service, customising blends to meet your project’s needs.

Lead time: Minimum Two Months