Fortnum & Mason 3D printed Awards

Bringing Mamou-Mani’s Design to Life with Advanced 3D Printing at Fab.Pub

Fortnum & Mason Food and Drink Awards

At Fab.Pub, we specialise in turning innovative designs into reality through advanced 3D printing and sustainable fabrication techniques. We were entrusted with the fabrication of the prestigious Fortnum & Mason Food and Drink Awards, designed by Mamou-Mani Architects. This project showcases how Fab.Pub used cutting-edge 3D printing technology and eco-friendly PLA bioplastic to craft an award that merges sustainability with intricate, parametric design.

Achieving Precision in Fabrication with Complex Parametric Design

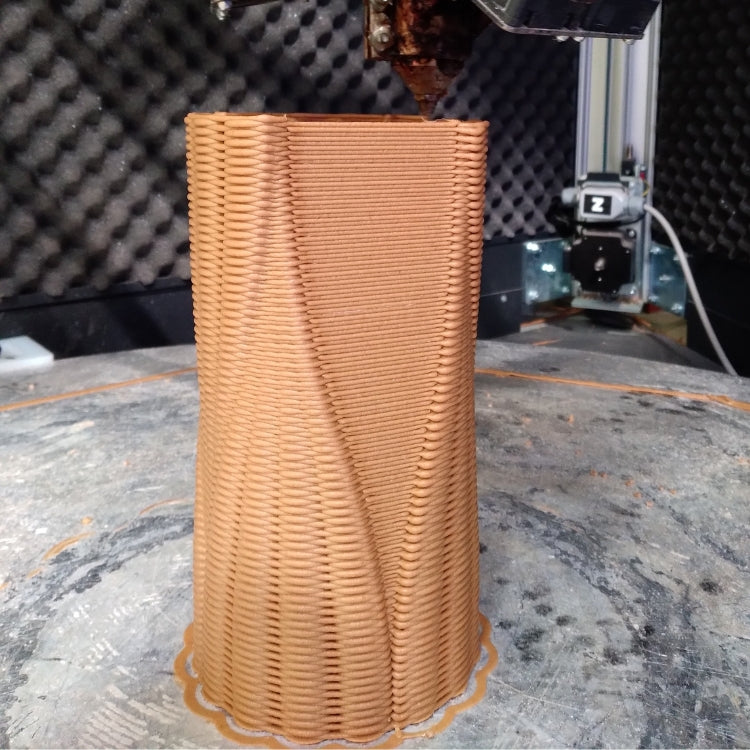

The challenge was not only to capture the intricate details of Mamou-Mani’s design but to do so sustainably. The awards featured a woven texture inspired by Fortnum & Mason’s iconic wicker hamper, which required the precise reproduction of complex geometries using parametric design. Fab.Pub needed to ensure that these delicate textures were faithfully recreated while using a material that aligned with the principles of the circular economy.

Mastering Fabrication with PLA Bioplastic and 3D Printing

Fab.Pub took the lead in the fabrication process, applying its expertise in sustainable 3D printing to translate Mamou-Mani’s intricate digital design into physical reality. We employed PLA bioplastic, a sustainable material made from fermented sugars and wood, to ensure the awards met both aesthetic and environmental standards.

By leveraging advanced 3D printing technology, we were able to accurately reproduce the intricate woven texture that gives the award its distinctive look. The fabrication process involved:

- Parametric Design Implementation: Using our precision-driven 3D printers to bring the complex digital design to life.

- Material Selection: Opting for PLA bioplastic, which reduces carbon emissions by 80% compared to conventional plastics.

- Efficient Production: Ensuring that each award maintained the highest quality while being fabricated in a sustainable and scalable manner.

Fabrication Innovation at Fab.Pub:

Sustainable Fabrication: We prioritised the use of PLA bioplastic, aligning with our commitment to eco-friendly production.

High-Precision 3D Printing: Fab.Pub’s advanced 3D printers enabled us to capture the intricate details of the parametric design, ensuring a flawless reproduction of the digital model.

Circular Economy Integration: Using materials that are not only sustainable but also industrially compostable, reinforcing our role as leaders in responsible fabrication.

Applications of the Solution

This project highlights Fab.Pub’s capabilities in producing high-quality, sustainable designs across various industries:

Award Fabrication: Creating bespoke, eco-friendly awards with a focus on precision and sustainability.

Product Design: Using advanced digital fabrication techniques to create products that balance form, function, and sustainability.

Custom Fabrication: Offering detailed, parametric designs for installations, products, and visual merchandising, all with an emphasis on environmentally conscious materials.

Want to bring your designs to life with sustainable, precise fabrication?

At Fab.Pub, we’re experts in turning complex digital designs into reality through our advanced 3D printing capabilities. Contact us today to learn how we can help you fabricate your next project with a focus on sustainability and precision.

Empower innovation with Fab.Pub's 3D printed solution